- Home

- /

- Services

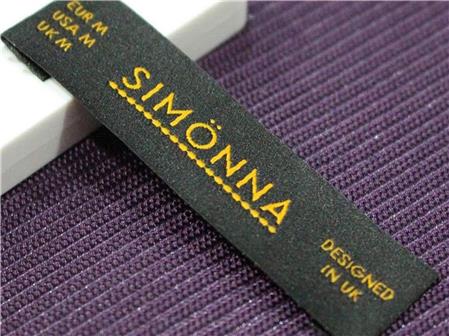

Woven label

Woven label

Woven labels, are used for product promotion and advertisement purposes in many industries, primarily textiles. Although it is mainly used in textile, it would be wrong to name this type of label as a textile label. Because it is used in many different sectors, especially in shoes. It is very important in terms of the permanent value of the brand on the product and adding the appeal to the product. Woven labels are named as satin, weft satin and taffeta (woven polyester) according to their production methods and quality types. Woven labels are indispensable for any company that trusts its product in terms of quality and attaches importance to brand prestige. Because the woven label is permanent and unlike many other accessories, it continues to be with the product and promote the brand as long as the product lives. In this sense, woven labels have a longer life than cloth printed labels, which are alternatives. Woven labels, which contain the company name, model, size and washing instructions and are used in almost all textile products for product advertisement, are used for product decoration as well as brand promotion in clothing. By the way, let's emphasize a very important point that needs to be mentioned; The woven label should be compatible with the cardboard label on the product and create a pleasant composition.

That's why it would be best for you and your brand to work with a company that has proven its expertise in woven labels and cardboard labels. The importance of the woven label is great in highlighting the product quality. It is of great importance for the product quality to come to the fore, to differentiate the brand, to emphasize it efficiently and perfectly, and to increase profitability and return on investment.

Brief Information About Manufacturing Stages and Woven Label

The first stage of woven label production is graphic work. The graphic work prepared in line with the customer's color, size and quality preference is presented in the computer environment or with digital output.

The pattern of the approved work is drawn. Depending on the customer's request, a one-to-one sample is prepared. And of course the sample work can be made more attractive with alternative colors. Woven label,

It can be beautified with applications such as polishing, sim, embossing during the manufacturing phase. Woven labels can be produced in the desired color, size and shape. The label, which started its production journey with the woven label machine,

It can be formed into the desired form with laser cutting or it can be brought to the desired size with normal cutting.

All these processes are of course shaped by the effort and meticulousness of a professional staff. Bordeaux Label, which has an important place among woven label companies, is always ready to offer the right solution for your needs.

We know the importance of the woven label for the brand and its power in terms of advertising and we serve accordingly.

- Some of the woven labels may be attached, although they are sifted during production. This is not an error. It is a necessity for the production to run. Please do not use (do not sew) the attached labels. Attached tags have been deducted from the total number.

- The maximum washing temperature for woven label is 60°C. When washing above this temperature, deformation in the structure of the label and fading in its colors may occur.

- Silvery labels are on average 30% more expensive than normal labels.

- Glossy labels are on average 85% more expensive than normal labels.

- The yarn thickness used in the woven label is generally 90 denier.

Join Our Newsletter

Be informed about innovations about us